Data-Led, Veteran-Focused: Radii Devices Supports First Definitive 3D Printed Socket in VA History

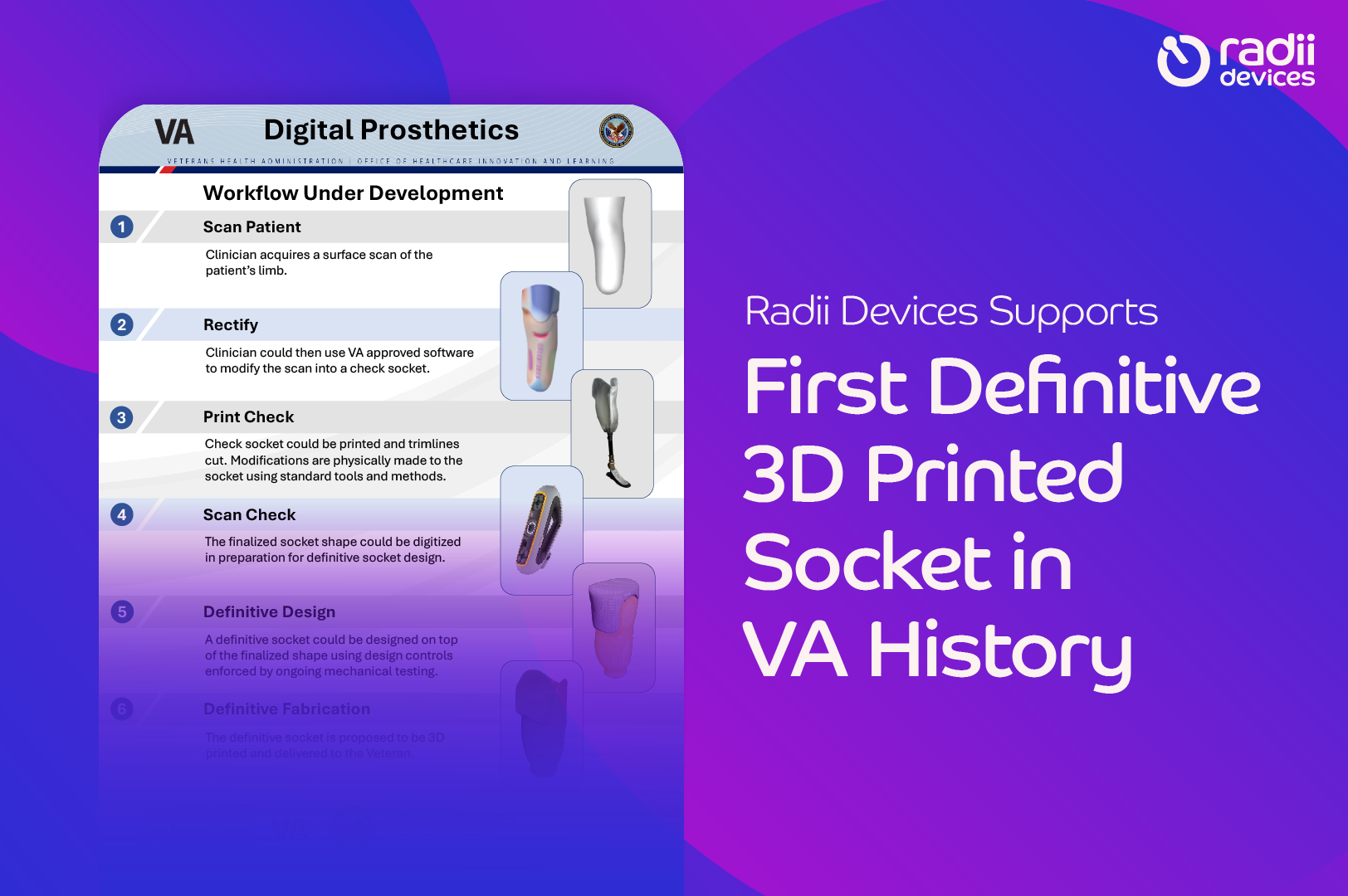

At Radii Devices, we’re building the digital infrastructure for the future of orthotics and prosthetics (O&P). That future became reality recently, as our technology helped deliver the first-ever definitive 3D-printed transtibial socket created through an entirely VA-integrated workflow.

This marks a major milestone — not only for us and our partners, but for prosthetic users across the U.S. healthcare system. Working alongside VA Puget Sound Health Care System’s X_Labs team and partners including HP and Red Duke Strategies, we supported a new, streamlined process to design, refine and deliver a personalized prosthetic socket to Veteran William Stuart — the first of its kind, made possible by data, evidence, and collaboration.

Our software, riiForm, enabled teams from across VA to securely share, assess, and improve clinical data throughout the socket design process. The result was a fully 3D-printed transtibial socket, manufactured collaboratively within the VA system.

“We’re not just building software — we’re helping shape what the future of prosthetic care actually looks like,” said Joshua Steer, CEO of Radii Devices. “To see that future delivered for someone who’s served — using tools that are scalable, clinical, and grounded in evidence — that’s the kind of progress we’re working towards.”

The final socket was printed using high-performance materials and finished with HP’s vapor smoothing process, before being assembled and fitted with Stuart. The design was both highly functional and deeply personal — featuring a U.S. Air Force emblem and wing details to honour Stuart’s service.

Radii’s U.S. Clinical Lead, Maggie Brooks, supported clinician training throughout the project to ensure the workflow could be applied reliably and confidently in a clinical environment.

“Training prosthetists to use these tools is about more than software,” said Brooks. “It’s about making digital collaboration feel natural and useful — helping clinicians see how data and design can work together to improve outcomes, even across a large and complex health system like VA.”

This project reflects the practical value of Radii’s approach: equipping clinicians with tools that fit into real-world workflows and support busy healthcare professionals. The project vision is to create digital process which can be accessed across the VA network, and we’re excited to continue working with our partners HP Additive Manufacturing Solutions, PVA Med and Red Duke Strategies to make this happen.